News

2023

MPM celebrates its 27th consecutive year accident free.

MPM maintains its ISO 9001/2015 certification.

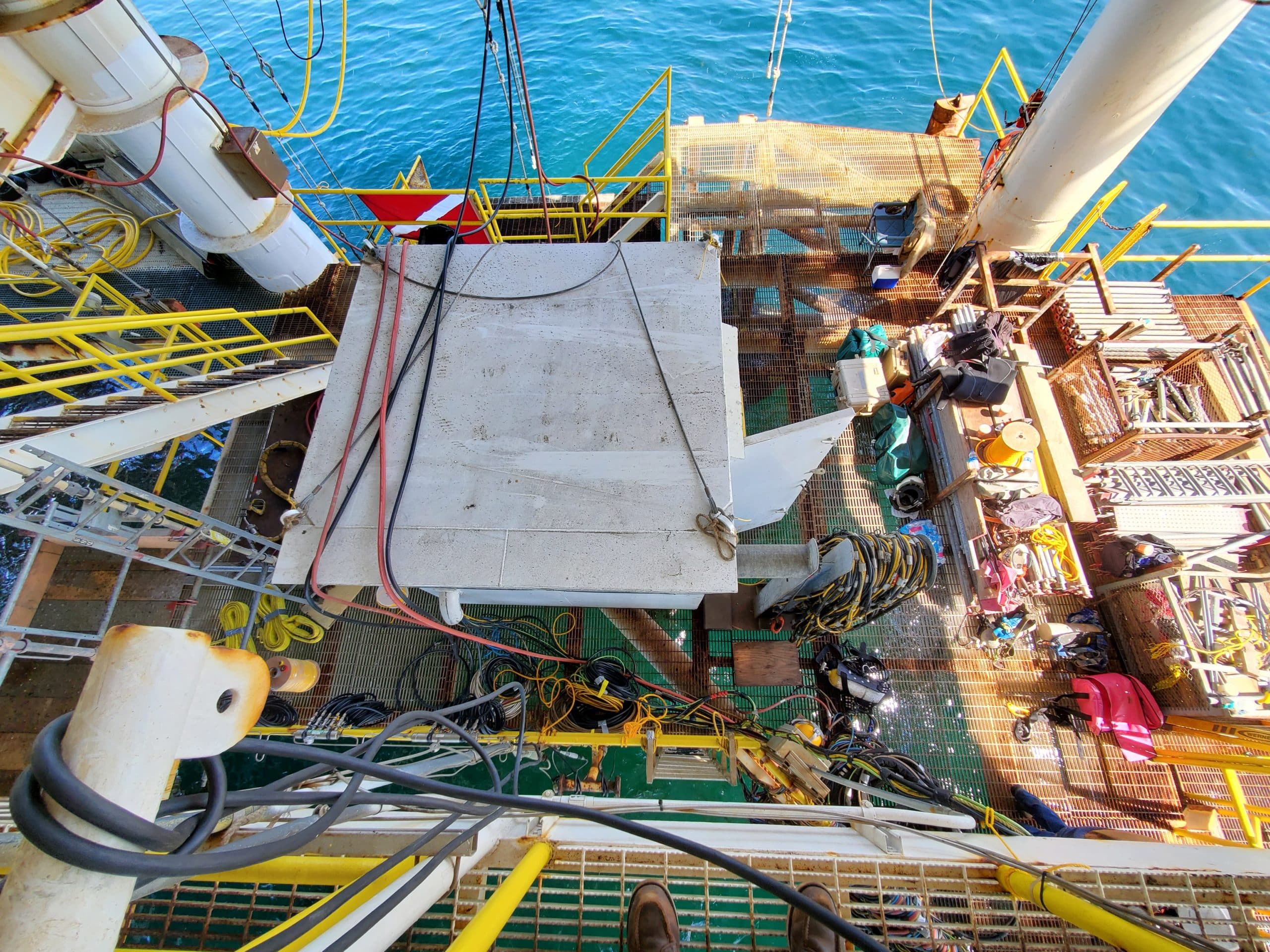

MPM plans and manages API RP 2A platform inspections and platform marine growth removal on the west coast incorporating diving and ROV inspections.

MPM plans and manages HazAn/HazID and subsequent field operations to remove a potentially hazardous barge bumper near a boat landing on an offshore platform.

MPM performs Level I CP drop cell surveys on multiple platforms and structures in California.

MPM manufactures 10 of its 400-amp impressed anode sleds for use in Alaska’s Cook Inlet.

2022

MPM maintains its ISO 9001/2015 certification.

MPM plans and manages marine growth removal and API RP 2A platform inspections on the west coast incorporating diving and ROV operations.

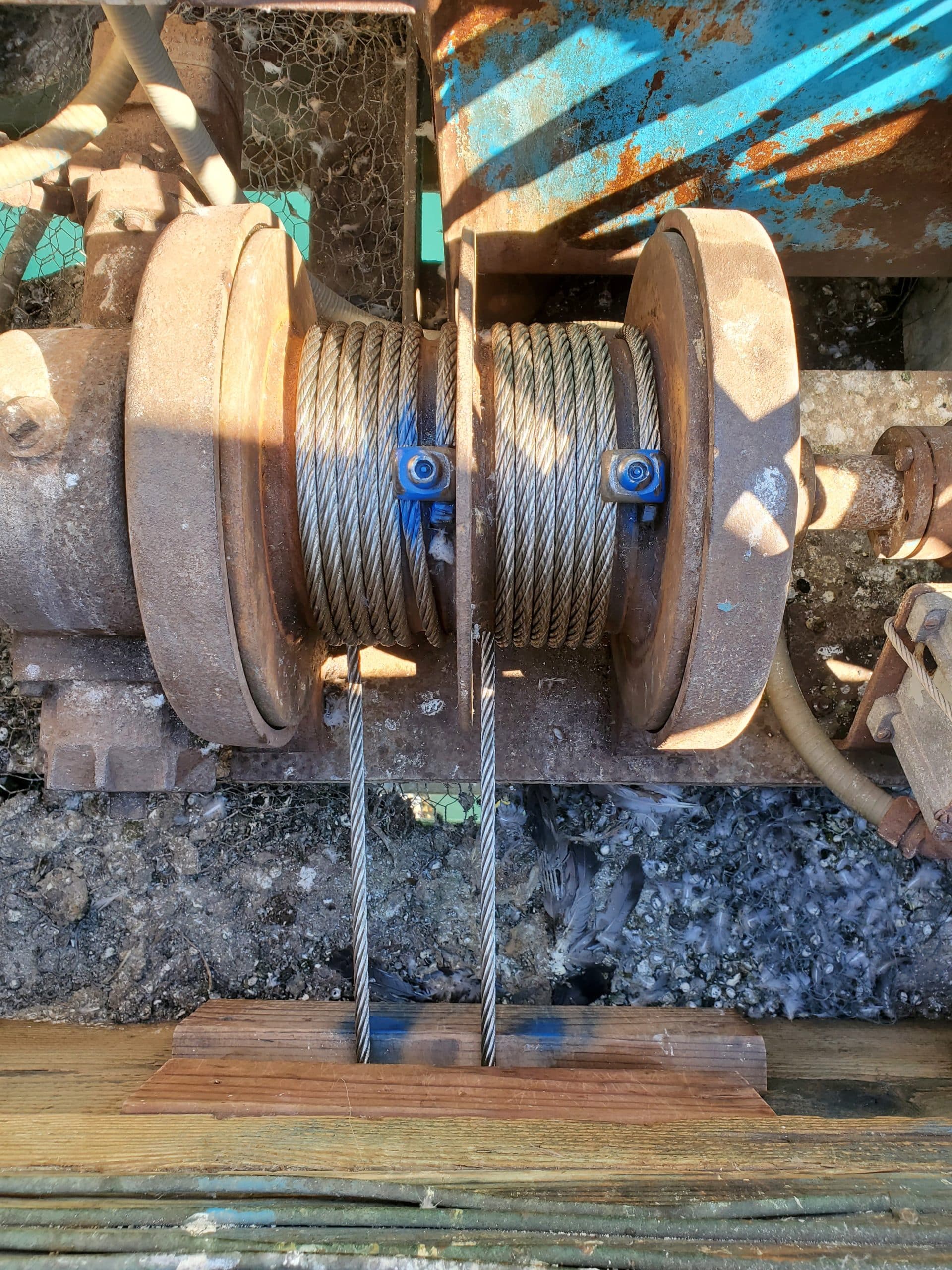

MPM plans and manages shallow and deep-water mooring overhaul operations up and down the south/central coast.

MPM plans and completes installation of 70 galvanic anode strings on west coast platform in 320 FSW

MPM plans and manages the annual inspection of pipeline supports located in environmentally sensitive waters.

MPM continues to support pier maintenance and repair operations on multiple piers.

2021

MPM celebrates its 25th consecutive year accident free.

MPM maintains its ISO 9001/2015 certification.

MPM plans and manages marine growth removal and API RP 2A inspection operations on various west coast platforms including diver and ROV inspections.

MPM services new client’s previously unmaintained mooring systems.

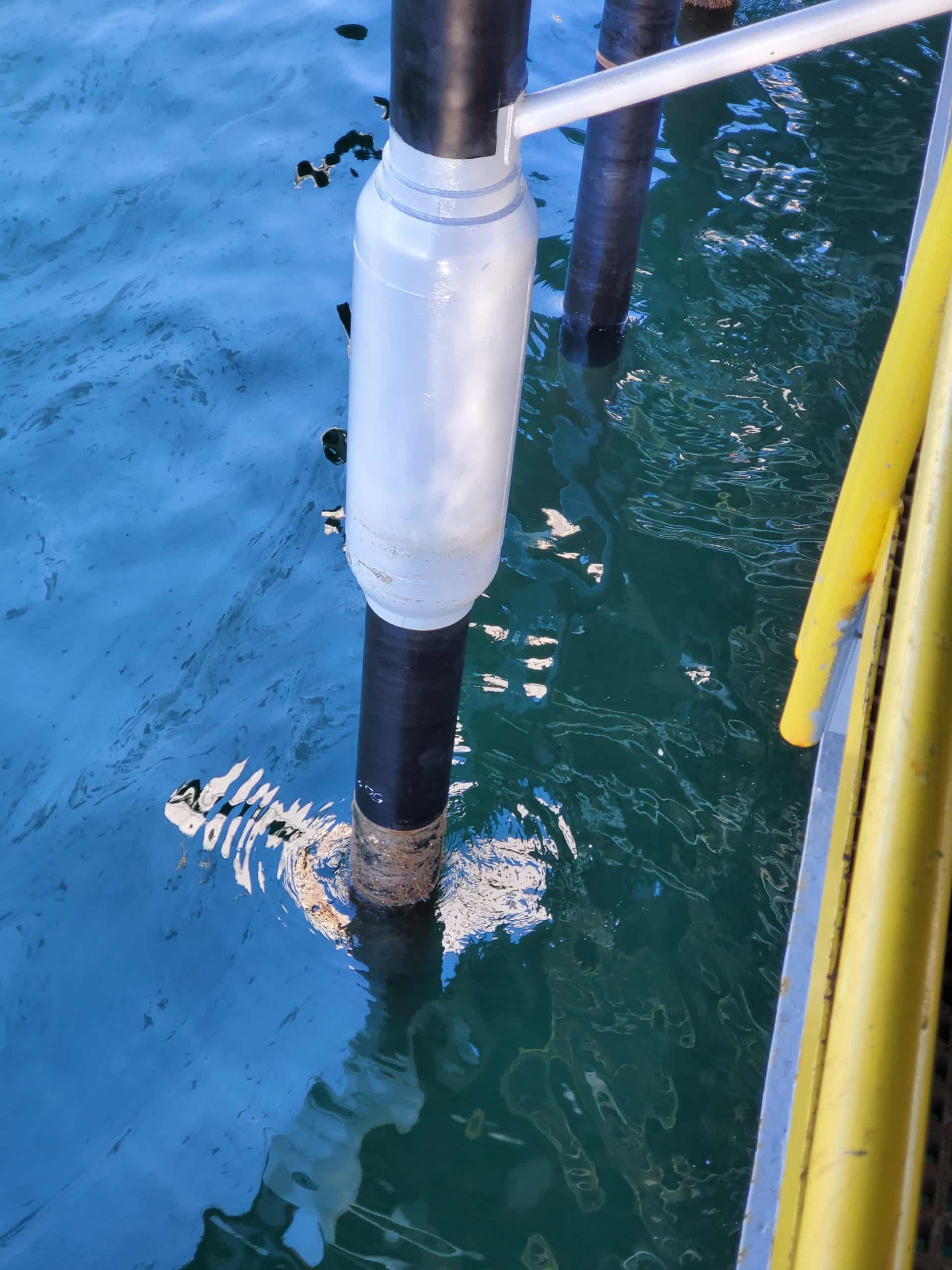

MPM plans and manages inspection and maintenance operations on a steel oil service pier including marine growth removal, removal of broken and damaged framing, structural repairs and installation of anti-corrosion pile wraps.

2019

MPM maintains its ISO 9001/2015 certification.

MPM plans, designs, and performs repairs on a pier critical to the California offshore oil industry. Repair efforts required close coordination with regulatory and environmental agencies and involved developing special tooling to perform the work within the constraints of the pier and in the surf zone.

MPM plans and manages mooring system maintenance for various systems in Santa Barbara and Ventura Counties.

MPM plans and performs inspections, repairs, and maintenance on an oil pier in Santa Barbara County.

2018

MPM upgrades its ISO 9001/2008 to ISO 9001/2015

MPM is contracted to find and repair a pipeline that had previously eluded contractors for two years. MPM provides planning, permitting support, and serves as prime contractor for the project. The pipeline is located and repaired within 48 hours.

MPM plans and manages repairs to concrete structural members on a California pier to restore deck loading capabilities. In addition, existing steel-encased pile supports are refurbished, with the corroded steel shells removed and replaced with fiber wrap.

MPM oversees the removal and driving of steel pile on a pier in sensitive California waters including planning, permitting support, and serving as prime contractor. The work is coordinated with topside marine mammal monitors and subsea acoustic monitoring during pile driving to ensure the safety of inhabitants of a nearby seal rookery.

MPM maintains its ISO 9001/2008 certification.

MPM supplies 15ea 80KW Class 1/Div 2 oil-cooled cathodic protection rectifiers.

MPM Upgrades Its Subsea Inspection Management System (SIMS) (Examples of system in action here.)

Marine Project Management, Inc. (MPM) has significantly enhanced its underwater facility cathodic protection (CP) survey system to include pipeline and structure UWI/UWILD integrity management features. Easily interfacing with most ROV systems, the system is being rebranded as the Subsea Integrity Management System (SIMS) and will reduce underwater inspection costs in offshore spread time, reporting, and post-survey evaluation. SIMS is available as a service for the US West Coast and Gulf of Mexico markets.

The system, comprised of both hardware and software, has been developed from the ground up using feedback form our clients and input and direction from our inspectors that have nearly a century of combined underwater inspection project experience. Features include:

- 4-Channel CP Data – SIMS ROV enhancements include two CP survey reference electrode pairs designed to collect proximity and electric field gradient (EFG) data using stab, remote reference, or trailing wire inspection techniques during the same operation. The software and hardware are configured to allow performance of each technique without surfacing the ROV for re-configuration. The redundant electrodes provide the additional benefit of real time accuracy testing and virtually eliminates the need to recover the ROV for failed electrode change-out.

- Data Keeping and Display – Inspection data can be logged continuously or manually depending on the type of survey being performed while being simultaneously overlaid onto ROV SD or HD video via a host of common video interfaces. Data available for recording and overlay include both primary and redundant CP reference electrode data, external inputs including navigation (XY, Lat/Long), “fix” information, external date/time, altimeter/depth data, and SIMS operator comments and location codes. SIMS time-stamped, on-the-fly structure location coding is intuitive and simplifies on site data entry, post processing, and future data management. Video overlay and recorded data clearly identifies the system grounding technique (stab or trailing wire/remote reference as ground) throughout the survey allowing efficient data post processing, evaluation, and reporting.

- MPM’s process and SIMS – MPM’s process includes developing a facility-specific, condition-driven work scope to eliminate unnecessary data collection and reduce inspection cost and can be exceptionally cost effective for pipeline systems. Using SIMS, transparency and traceability of grounding technique and offsets is preserved throughout the survey to aid in post inspection data evaluation and quality control.

2016

MPM celebrates its 20th consecutive year accident free.

MPM maintains its ISO 9001/2008 certification

2015

MPM’s Cathodic Protection Survey System (CPSS) software is upgraded to Revision 3. The software now supports dual EFG measurements (4 channels of CP collection) and platform inspection modules. Fully customizable video overlay to external monitors and recording devices also featured.

MPM maintains its ISO 9001/2008 certification

2014

MPM receives patent on new “Bag Anode Kit” ICCP system. This light duty system is provided as an anode sled “kit,” and is designed specifically for shallower depths and/or smaller marine structures, providing an output of up to 250 amps per sled.

2013

After exhibiting outstanding Quality Management Systems in both product manufacturing and engineering services, MPM obtains ISO 9001:2008 certification.

MPM manufactures and ships its 400-amp impressed current anode sleds for delivery and use in Alaska’s Cook Inlet.